Firm Ground Boots

Designed to make an impact. When the going gets tough.

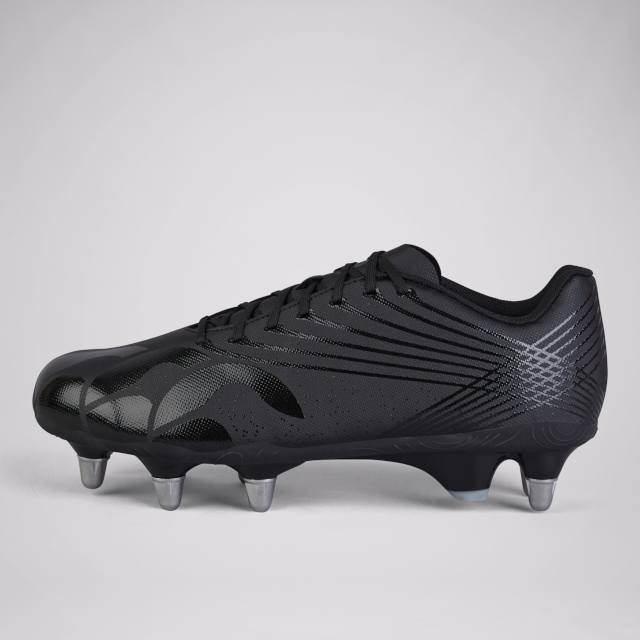

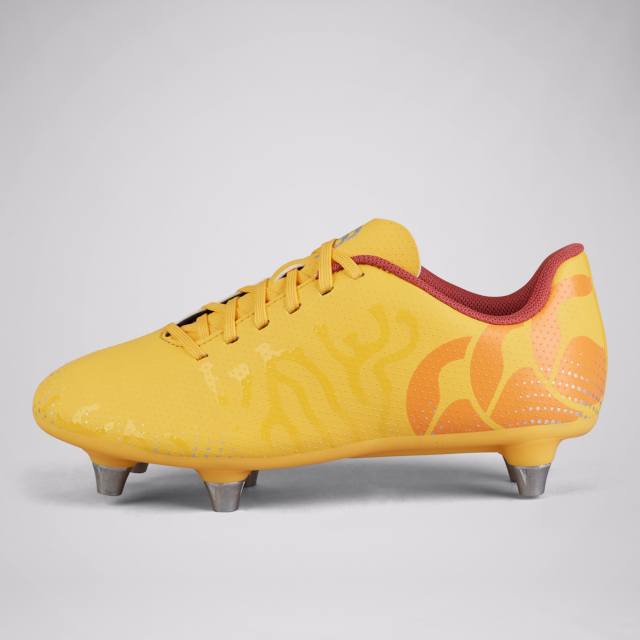

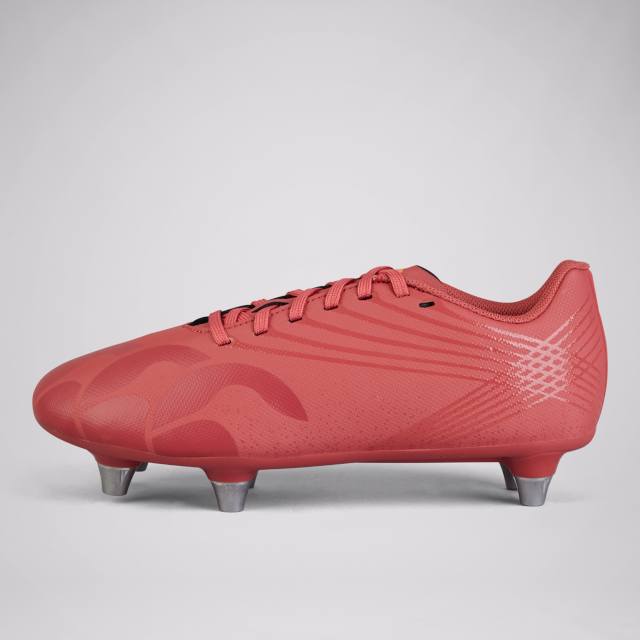

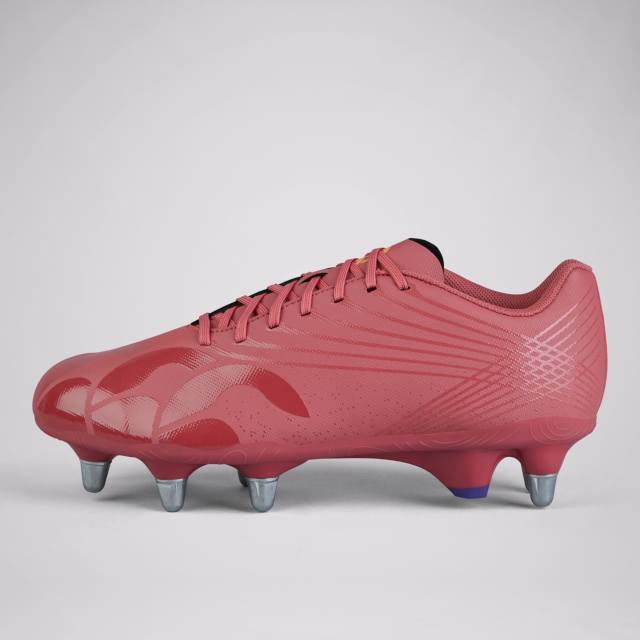

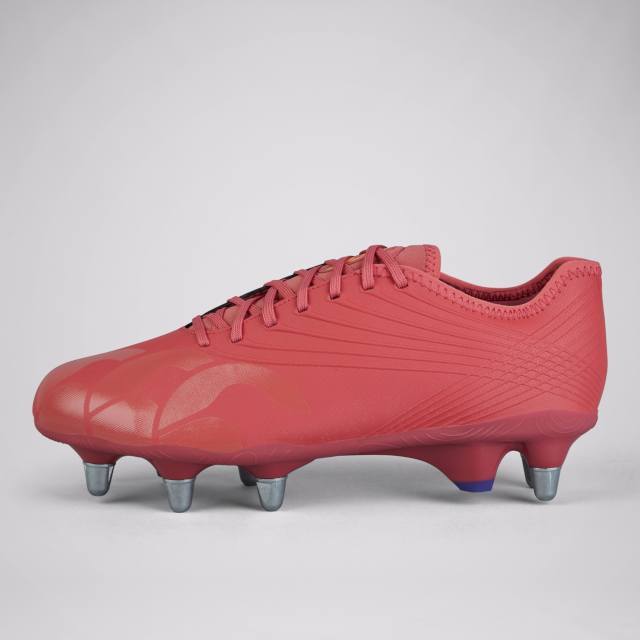

Soft Ground Boots

Designed to help you dig in. Because no pitch is perfect.

Boots for Forwards

Designed for scrums, rucks, marginal gains and battling over the try line.

Boots for Backs

Designed for drive, stability, agility and legging it up the pitch.

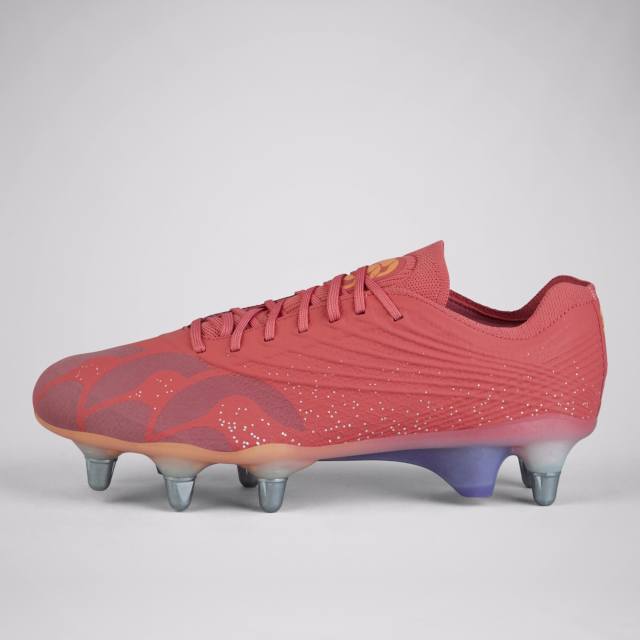

Level Up Your Game With Our Lightest Boot Ever

Fast is out there. Speed Infinite Elite is our lightest rugby boot ever, optimised to ensure that you can squeeze every ounce of acceleration and speed out of your game. The weapon of choice for some of the most lightning quick backs in the game - Adam Radwan, Ellie Kildunne, Mack Hansen and Jodie Ounsley to name a few. But what does this mean for you? We take a dive in to see how Speed Infinite Elite can level up your speed game.

Please log on to Pentland Connect to learn more.

Login here